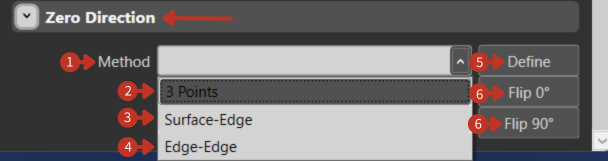

Zero Direction Interface

What You See

An interface titled "Zero Direction" which contains a dropdown menu for "Method" with options such as "3 Points," "Surface-Edge," and "Edge-Edge." Additionally, there are buttons for "Define," "Flip 0°," and "Flip 90°."

Reference direction definition for fiber orientation in composite structures

What It Means

This part of the software interface is designed for specifying the orientation of a zero or reference direction in relation to the geometry being worked on.

Method Selection

"Method" Dropdown Menu: Allows the user to choose the method for establishing the zero direction. The options available suggest different ways to define this orientation based on geometric features or points.

Available Methods

-

"3 Points": This option sets the zero direction based on three selected points within the geometry, defining a plane.

-

"Surface-Edge": Establishes the zero direction based on the alignment of a surface and an edge, which could be used to define a reference angle or plane.

-

"Edge-Edge": This is used to set the zero direction at the intersection or angle between two edges.

Control Buttons

-

"Define" Button: Finalizes the selection and orientation of the zero direction once the user has chosen a method and specified the necessary points or features.

-

"Flip 0°" Button: Reverses the zero direction by 180 degrees along the same axis.

-

"Flip 90°" Button: Rotates the zero direction by 90 degrees, changing the orientation perpendicularly.

Importance of Zero Direction

The zero direction is critical for:

- Defining fiber orientation angles

- Ensuring consistent ply alignment

- Coordinating multi-ply laminates

- Meeting design specifications

- Optimizing structural properties

Setup Guidelines

- Choose method based on geometry type

- Select clearly identifiable reference features

- Verify direction matches design intent

- Document zero direction for repeatability

- Test with single ply before full laminate