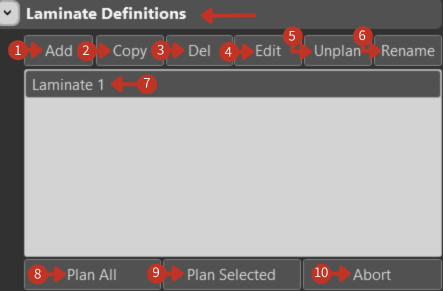

Laminate Definitions and Configuration

Create, manage, and configure laminate definitions for composite manufacturing operations, including material parameters, ply configurations, and layup strategies.

Overview

Laminate definitions provide the foundation for composite manufacturing by defining material properties, layup sequences, and manufacturing parameters for your parts.

Laminate Definitions management with planning controls

Management Functions

Definition Management

- Add: Create new laminate definitions with custom parameters

- Copy: Duplicate existing configurations for variations

- Edit: Modify definition properties and parameters

- Delete: Remove unused laminate definitions

- Rename: Update definition names for better organization

Planning Operations

- Plan All: Process all laminate definitions for manufacturing

- Plan Selected: Generate plans for specific laminates only

- Unplan: Reset planning status and clear generated paths

- Abort: Stop current planning operations

Configuration Components

Material Parameters

- Material type selection

- Thickness specifications

- Fiber orientation angles

- Mechanical properties

Ply Configuration

- Individual ply definitions

- Stacking sequence

- Fiber directions

- Drop-off patterns

Layup Areas

- Manufacturing zones

- Boundary definitions

- Application areas

- Restricted regions

Process Parameters

- Temperature settings

- Pressure specifications

- Speed parameters

- Quality requirements

Configuration Workflow

- Create Definition: Add new laminate with basic properties

- Material Setup: Define material types and properties

- Ply Configuration: Set up individual plies and sequences

- Area Definition: Define manufacturing areas and boundaries

- Parameter Tuning: Adjust process-specific settings

- Validation: Verify configuration completeness

- Planning: Generate manufacturing plans

Advanced Features

Linked Mold Integration

- Mold association

- Geometry constraints

- Manufacturing boundaries

- Quality checkpoints

Motion Control

- Approach strategies

- Retract movements

- Speed profiles

- Path optimization

Heater Configuration

- Temperature control

- Heating zones

- Thermal profiles

- Process monitoring

Best Practices

Definition Organization

- Use descriptive naming conventions

- Group related configurations

- Maintain version control

- Document changes

Parameter Optimization

- Start with manufacturer recommendations

- Validate through testing

- Optimize for quality and speed

- Document successful parameters